Sheet piling with pre-drilling & all drilled RD pile wall works

Cost-effective sheet piling & pre-drilling sub-contract work

We offer wide variety of solutions to complete your sheet piling tasks. We also offer pre-drilling for rocky sheet piling conditions to eliminate harmful vibrations common with sheet piling to minimize the environmental and utility risks. Machines are equipped with 400 – 1500 KN hydraulic variable vibro-hammers whereas fixed leader of up to 30 meters can handle 27 meters elements in surface installed with maximum hydraulic power of 670 KW. Crane mounted MS24 with 250 KW hydraulic power is suitable for small offshore work. All machines have variable eccentric motion control systems and suitable for projects with demanding environmental requirements such as being in close proximity to buildings etc.

Projects from past

New patented drilled pipewall with outside fluid flushing.

Projects of the past

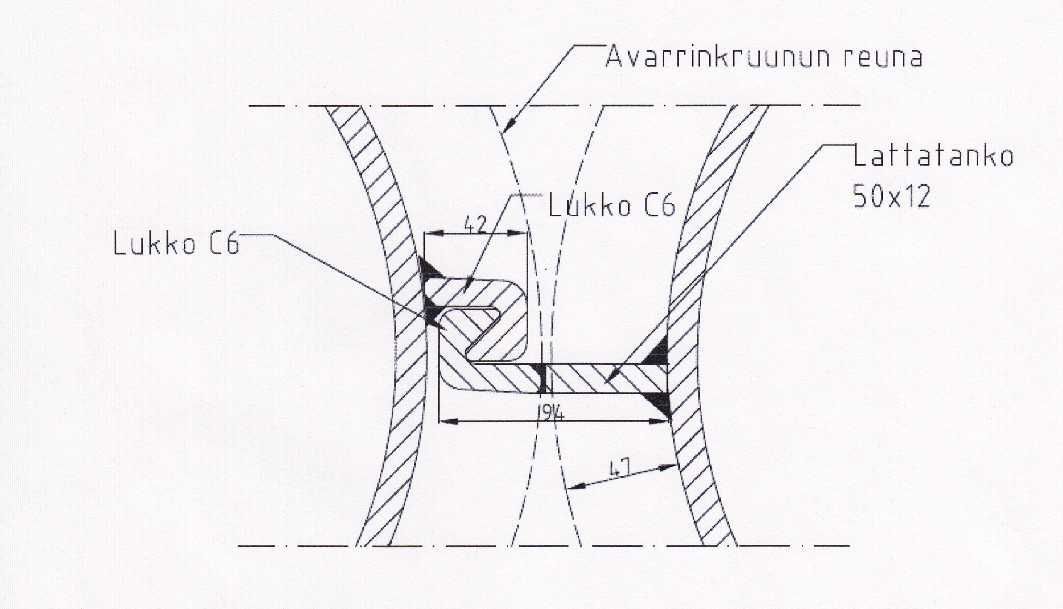

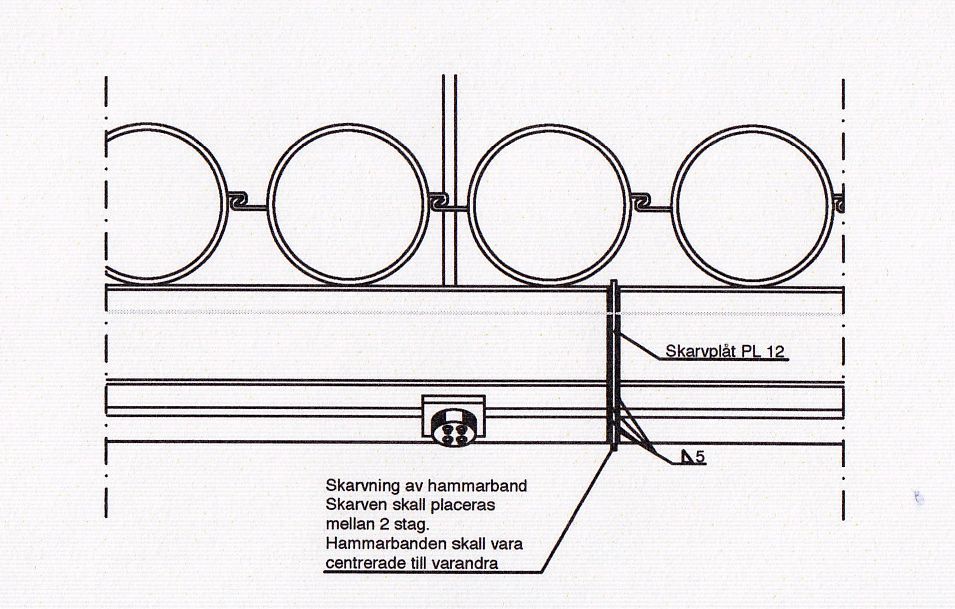

We completed the first drilled pile wall in Scandinavia 2010 that called for installation of 200 pcs of DN400 Ruukki piles equipped with interlocks and used special Atlas Copco designed bits for the installation.

New PATENTED installation of interlocked drilled pipewall utilizing outside flushing and water hammer or modified air hammer in large diameters.

Safest installation method in urban or hazardous areas but yet suitable in all formations.

- Ideal for installations of pipes next to existing buildings and foundations. High Frequency water hammers are know to cause very little distruption and extremely low levels of Peak Particle Velocity (mm/s). Water flushing causes no shockwaves and in fact outside flushing works to fill up all potential cavities in the nearby formation.

- Water tight wall can be closed in the bottom by injection through the casing and cement grout will follow the path of flushing medium earlier up the annulus of installed pipe wall.

- No need to secure the bottom of the wall with dowels as piles are secured in the bedrock for horizontal loading.

- Installed water tight wall can also handle vertical loading.

- Suitable for any traditional jet grouting water tight wall application as method causes no settlements.

- Installation process is fast and watertight wall is ready to take loading after just one week.

Berlin walls Combi and pipewalls

We can install Berlin walls with up 600 mm in diameter and water drilling with the unique and proprietary Safe Flow technology up to 300 mm. Berlin wall can be installed with unique Safe Flow Drilling system causing absolute minimum disruption to adjacent buildings and structures. Safe Flow system is the only proven system, which does not create shockwaves or over flush the drill hole. With Safe Flow system a water tight pipe wall can be installed and casings used directly for the bottom injection to seal the between the wall bottom and the rock. See article Safe Flow System Södertälje Lyftbro.